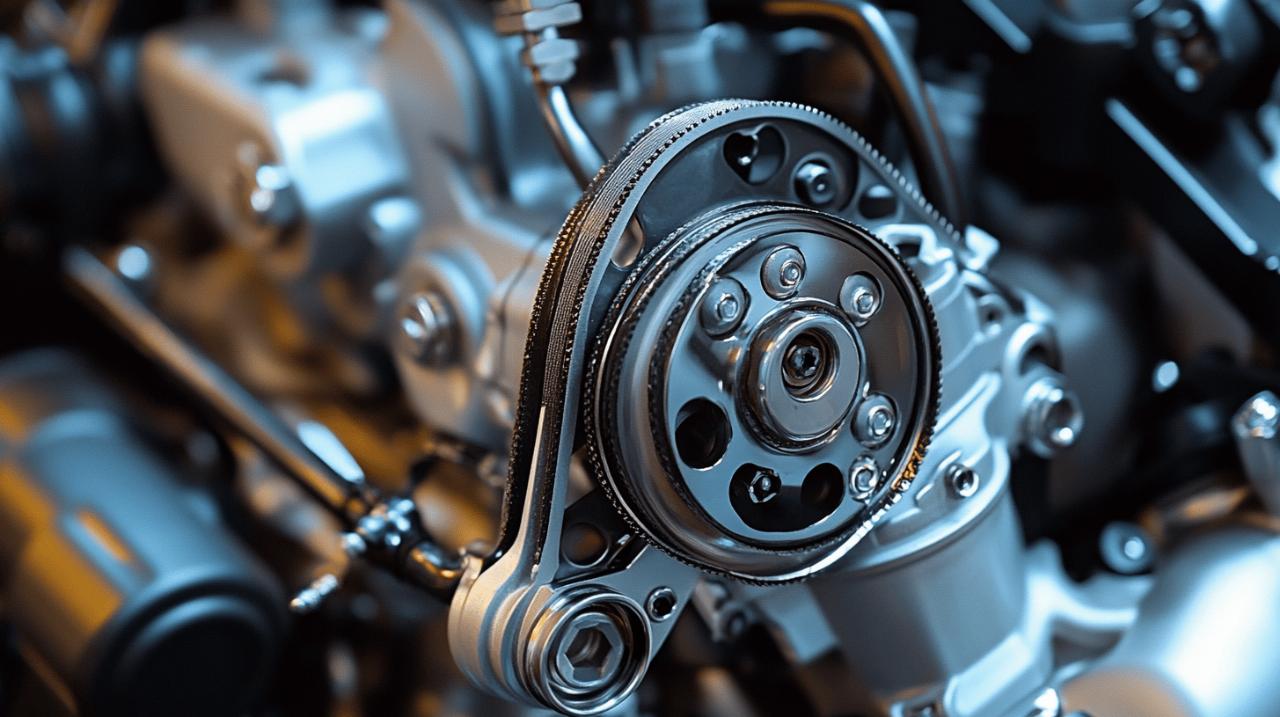

Keeping your vehicle’s engine running smoothly requires attention to critical components that often go unnoticed until they fail. Among these, the timing belt plays a crucial role in ensuring your engine operates correctly. This guide will help you understand how to maintain this essential part properly and avoid costly repairs down the road.

Understanding the Importance of Timing Belt Checks

The timing belt, also known as a cambelt, is a vital component that synchronises the rotation of the crankshaft and camshaft in your engine. This synchronisation ensures valves open and close at precisely the right moments during the combustion process. Many motorists overlook this component until it’s too late, but as automotive experts at https://www.motorpublish.it/ emphasise in their recent timing belt maintenance guide, regular inspections can prevent catastrophic engine damage.

Why regular inspections matter

Regular checks of your timing belt are absolutely crucial because a failure can lead to severe consequences. When a timing belt breaks while driving, your engine will stop functioning immediately, potentially leaving you stranded and facing significant repair costs. In interference engines, which are common in many modern vehicles, a broken timing belt can cause pistons to collide with valves, resulting in extensive internal engine damage that might cost thousands of pounds to repair.

Recognising the First Signs of Wear

Being proactive about identifying early warning signs can save you from a roadside breakdown. Look for visual indicators such as fraying along the edges, cracks on the belt surface, or missing teeth. These signs suggest that your timing belt is degrading and needs attention. Additionally, listen for unusual noises coming from the engine compartment. A ticking or slapping sound could indicate that the timing belt is loose or wearing unevenly, affecting the engine synchronisation.

Following manufacturer guidelines

Every vehicle has specific requirements for timing belt maintenance, making it essential to follow the guidelines provided by your car manufacturer rather than relying on general advice.

Finding your vehicle’s service schedule

The recommended replacement interval for timing belts typically ranges from 50,000 to 100,000 miles, or every 5 to 10 years, depending on the make and model of your vehicle. This information can usually be found in your owner’s manual or service booklet. For instance, Ford recommends wet timing belt replacement at 144,000 miles or 120 months, while Vauxhall suggests replacement every 6 years or 60,000 miles, whichever occurs sooner. If you’re unsure about your specific vehicle’s requirements, consult a qualified mechanic who specialises in your make and model.

What happens when you ignore recommended intervals

Failing to adhere to the manufacturer’s recommended service intervals for timing belt replacement is a risky decision that can lead to severe consequences. When a timing belt exceeds its intended lifespan, the rubber material deteriorates, becoming brittle and prone to sudden failure. This deterioration occurs regardless of how well you maintain other aspects of your vehicle. The average cost to replace a timing belt is approximately £468, including parts and labour, which is significant but pales in comparison to the potential expense of repairing engine damage caused by a broken timing belt.

Identifying critical warning signs

Even with regular maintenance, timing belts can sometimes fail prematurely. Knowing what to look for can help you address issues before they escalate into major problems.

Visual indicators of timing belt damage

Performing a visual inspection of your timing belt can reveal early signs of wear that warrant immediate attention. Remove the plastic cover protecting the timing belt and examine it closely for cracks, which indicate the rubber is deteriorating. Look for signs of glazing or shiny spots on the belt surface, suggesting it’s hardening with age. Check for fraying edges or missing teeth, as these directly impact the belt’s ability to maintain proper engine timing. Oil contamination is another critical issue to watch for, as oil can degrade the rubber compound and accelerate wear.

Concerning engine noises to watch for

Your engine can communicate potential timing belt problems through various sounds. A ticking or clicking noise from the engine, particularly during startup or acceleration, may indicate that the timing belt is loose or that some teeth are damaged. Rough idling when your vehicle is stationary suggests the engine is not running smoothly due to timing issues. In some cases, you might notice a slapping sound, which could mean the belt is excessively loose. These audio warnings should never be ignored, as they often precede complete belt failure.

Seeking professional assessment

While some maintenance tasks can be handled by DIY enthusiasts, timing belt inspection and replacement generally require professional expertise.

When to Consult a Qualified Mechanic

If your vehicle is approaching the manufacturer’s recommended interval for timing belt replacement, it’s time to schedule an appointment with a qualified mechanic. Similarly, if you notice any of the warning signs mentioned earlier, professional assessment is warranted even if you haven’t reached the recommended mileage. This is particularly important for vehicles with wet timing belts, which operate in an oil-lubricated environment and require specialised knowledge to service properly. Common vehicles using wet timing belts include Ford EcoBoost engines, various Peugeot and Citroen models, and some Volkswagen Audi Group vehicles.

What to Expect During a Timing Belt Inspection

During a professional timing belt inspection, the mechanic will typically examine the condition of the belt, checking for wear patterns, cracks, and proper tension. They will also assess related components such as tensioners, idlers, and the water pump. The inspection might involve removing covers or other components to gain proper access, which is why this task is best left to professionals with the right tools and expertise. A thorough assessment should include verification that timing marks are correctly aligned, ensuring the engine components are properly synchronised.

Timing belt replacement best practices

When the time comes for a timing belt replacement, following best practices can save you money and prevent future issues.

The case for simultaneous water pump replacement

Many automotive experts recommend replacing the water pump when you replace the timing belt, particularly if the timing belt drives the water pump. This approach makes financial sense because much of the labour cost involved in replacing the timing belt comes from accessing it, which requires the same disassembly needed to reach the water pump. Since water pumps often have a similar lifespan to timing belts, replacing both at once can prevent the need for additional labour costs in the near future. Additionally, if a water pump fails after a new timing belt is installed, the resulting coolant leak could damage the fresh timing belt.

Selecting quality components for longevity

When replacing your timing belt, choosing high-quality components is crucial for ensuring reliability and longevity. Look for parts that meet or exceed Original Equipment Manufacturer standards rather than opting for the cheapest available options. Quality kits like those from reputable manufacturers include not just the belt but also tensioners, idlers, and sometimes water pumps. These comprehensive kits ensure all related components are replaced together, reducing the risk of premature failure. Using genuine or high-quality aftermarket parts might cost more initially but provides greater peace of mind and potentially longer service intervals before the next replacement becomes necessary.